© Copyright COSMEK srl all right reserved legal Informations

Machine and tools for special product

I T A L I A N F I L T E R S M A C H I N E S

Machines

TECNICAL DATA

• production of 200 pcs/hr or more

• min filter diameter: 40 mm

• max filter diameter: 100 mm

• min filter height: 60 mm

• max filter height: 110 mm

• automatic tubes feeding

• possibility of using aluminum, plastics, cardboard tubes, with or without

collar, closed from a side or completely open

• complete filter sealing with hot-melt glue

• laser sensor for diameter measurement

• paper-tension regulation with electronic control

• automatic discharge with manipulator

• program management with PLC

• electronic keyboard on board the machine

• automatic problems-solving procedures to reduce the operator work.

• hot-melt dispenser complete with pipes of high temperature and special

glue-guns

• possibility for the operator to manage 4 machines ( an adequate education

of the operator is necessary and the packing of the finished filters is

excluded)

•extremely compact construction

coiling drum machines (fuel filters)

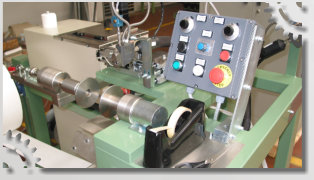

The automatic machine BA20 offers the advantage of a strong

and reliable construction, simple and equipped with the best

technical solutions at the same time.

An ample electric cabinet contains the control's electronics. The

controls, essential but complete , allow the total control of

the productive process without confusions for the operator. The

commands are friendly and easy to use. The machine, can be

rapidly adapted at the various types of filters today in use. All the

operations, from the tube loading to the paper feeding, are

executed in complete automatism of the machine. A special

sensor defines the filter diameter that could be regulated

immediately by the operator. The machine equipment

includes a tube feeder and the Hot-melt dispenser.

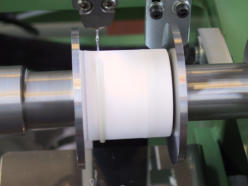

The semi-automatic machine BS1 is proper for firm requiring the

best quality with a modest investment.

The compact construction is equiped with all materials required for a

perfect and safe use. The machine, extremely versatile, is quickly

and easily adaptable to the different types of filters currently

produced. The operations of loading-tube, paper-cutting, filter-

discharge and final external sealing are manually executed. A special

sensor defines the filter diameter that could be regulated immediately

by the operator. The machine equipment includes the console for the

hot-melt dispenser and two glue guns; the first for the automatic

operations of tube and paper pasting, the second for the final

external filter sealing.

TECNICAL DATA

• semi-automatic, it needs the presence of only one operator

( or 2 for more performance in production )

• production of 100 pcs/hr or more

• min diameter : 40 millimeters

• max diameter :100 millimeters

• min height : 60 millimeters

• max height : 110 millimeters

• manual tubes feeding

• possibility of using aluminum, plastics, cardboard tubes, with or

without collar,closed from a side or completely open

• manual paper cutting

• laser sensor for diameter measurement

• paper-tension regulation with electronic control

• manual discharge of the finished filter

• electric control panel on the machine

• hot-melt dispenser complete with pipes of high temperature

and special glue-guns

• extremely compact construction