© Copyright COSMEK srl all right reserved legal Informations

PLEATING MACHINES

Machine for pleating paper or syntetic media

I T A L I A N F I L T E R S M A C H I N E S

Machines

Not all the accessories are available

for all type and/or configurations of the machines

machine for panel air filters

machine for circular air filters

machine for oil filters

machine for cabin filters

unwinder

automatic paper joining unwinder

embossing rollers

In this photo there is a roll of big dimensions.

pleats number marking

trimming and pre-cutting

After the pleating process it assures

good pleat bondage.

This process is particularly useful when producing panel filters

as the natural paper curling can be a hindrance.

Available many model whit lamps or hot plate.

post-heating system

trapezoidal system

Furnished in alternative to the simple unwinder, it

automatically joins the paper without stopping the machine.

This joins the working roll to a previously prepared roll,

avoiding boring and unproductive production halting in order to

change the roll.

The maximum diameter of a roll of paper is 1200mm.

The maximum width of a roll of paper is 600mm.

These are composed of two shafts mounted on a solid

structure.

The shafts have hardened steel blades which cut the paper to

obtain the desired height of the pleat.

A different embossing roller "group" is necessary for each

pleat height.

It is possible to create, accordingly to Customers’ drawing,

special knives, in order to obtain particular profiles, on top of

folded paper.

Cosmek can manufacture rolls suitable for all the old machines

of the customers.

Is automatically done by a spray gun at every pre-set count

set by the operator on the appropriate device.

In alternative it’s possible to equip the automatic cutter with a

new sensor that directly count the pleats, without the

necessity of the ink spot.

A paper trimming system can be placed before the embossing

rollers for particular requirements.

This group is composed of two loose blades, which descend

using a pneumatic slide.

These blades, which can be quickly activated and regulated,

are useful when the paper bobbins have been badly finished

and have irregular levels or for those who need to get more

strips simultaneously.

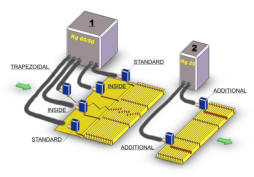

With our machines it is possible to produce filters with

trapezoidal profile.

This special system manages the job in a fast an easy way

with software. The system puts the glue in a diagonal way over

the paper.

System is complete of: electro-mechanical slide,electrical

engine and electrical drive CNC.

The cut is not included: it is necessary to cut filters externally

to the pleating machine (with other machine).

In order to guarantee a good manoeuvrability and a good cut,

the paper must be at ambient temperature.

This kind of cooling group is useful if a post-heating or oven

system is used.

Available many model.

cooling

Placed at the end of the line, with fix blade.

Cut made whit direct count of the number of the pleats without

the use of ink spot. It is mounted on it’s own structure.

With motorized slide and fix blade.

Similar to the pneumatic slide version, it is provided of a

electric motor slide. If compared with the pneumatic version it

has better speed performances, it is more silent, it has no

collision of end line and it is provided of a new pleats counting

system. Moreover the system recognize in automatic a

blocking of the blade and try to solve it automatically.

Special automatic cutter, at the end of the line with fixed

blade (cut with ink spot) mounted on its own structure.

Cut on the lower part of the pleat. It is designed for the cut

cold and not-glued paper. It is specific for oil filters and very

compact paper. It’s provided of 2 lateral motorized belts that

pick up pleats and guide them into the cut zone.

Cut system with length.

A sensor detects the length of the filter and activates the cut

independently from the number of pleats, or together in

combination with that number. Provided with touch screen

control panel. Filter length between 100 and 500 mm.

Conveyor belt at the entrance of the automatic cut,

made in aluminum profiles, with speed control on the main

control panel and synchronized speed with the machine

Provided with lateral guides and protection tunnel at the

entrance of the cutting device. It is necessary to use it when

there is a curing oven before cutting machine.

Conveyor belt at the end of the automatic cut, made in

aluminum profiles, with speed control on the main control

panel and synchronized speed with the machine.

Provided with protection tunnel at the exit of the cutting

device.

Table at the end of the line, to perform manual cute,

made in aluminum profile and plate in stainless steel.

Various paper holders are available:

-integrated to the pleating machine

-separated from the pleating machine

-with easy loading

-motorized

-with electronic or mechanical tensioning

For every machine and need we have the right solution.

The supporting arms on the roll holder have the possibility of

being lowered so the roll of paper no longer needs to be lifted.

This is very useful considering the weight of a roll of paper

with a width of 700mm.

The maximum diameter of a roll of paper is

1000mm or 1200mm.

pre-heating system

Pleating, on some types of paper can result to be a difficult

process.

To improve the possibility to process these types of paper a

preheating or humidifier group can be used.

Available many model whit lamps or hot plate or gas.

CUT MACHINE for trapezoidal filters

additional glue strip

for creation of additional glue strip at the top of the pleats.

It includes an air cooling system (compressed air needed).

The system is placed on the conveyor belt at the exit of the

pleating machine.

glue dispenser

Available many model and brand.

Cosmek supply this option like the request of the customer.

automatic cutter

web guiding

Automatic system with optical sensor capable of

correction +/- 10 mm.

It is useful for the alignment of paper rollers that are not

perfectly cut or with paper that use to wave. It is placed

between the unwinder and the group of tensioning rollers,

before entering the embossing rollers group.